Effluent Treatment Plant (ETP)

Effluent Solutions That Align With Industry

At Aaron, we design and deliver robust Effluent Treatment Plants (ETPs) that help industries manage, treat, and discharge their wastewater responsibly. Whether dealing with chemical-laden effluents, high COD/BOD levels, or strict regulatory discharge norms, our systems are engineered to ensure safe disposal or potential reuse.

Tailored ETP Solutions for Every Sector

Aaron’s ETP systems are engineered to serve a wide range of industrial sectors, each with unique wastewater challenges and compliance demands. We customize every solution to meet specific effluent profiles, industry standards, and operational goals.

Textile & Dyeing Units

Effluent from dyeing and printing processes contains high levels of color, COD, and chemicals — our systems treat and neutralize these pollutants for compliant discharge or reuse.

Chemical & Petrochemical Plants

We handle complex chemical effluents with high toxicity and variability, ensuring safe treatment and removal of hazardous substances.

Food & Beverage Processing

Our systems treat wastewater with high organic loads, fats, and oils, ensuring safe disposal and enabling partial reuse in non-potable operations.

Pharmaceutical Industries

Pharma wastewater requires precise removal of APIs, solvents, and high BOD/COD loads. We deliver validated, high-performance ETPs to meet strict norms.

Oil & Gas Facilities

From refinery discharges to produced water, our ETPs are built for durability and performance in heavy-duty environments.

Pulp & Paper Mills

These facilities generate high-volume effluent with fibrous and chemical content. Our systems are tailored for efficient solids separation and treatment.

Frequently Asked Questions

Explore Our Other Solutions, Services & Technologies

Integrating proven treatment processes and advanced technologies to deliver reliable, high-performance water management systems built for long-term operation.

Sewage Treatment Plants

We design and build high-efficiency STPs using proven biological and physical-chemical processes to ensure compliant, odor-free discharge or reuse. Our expertise covers advanced automation, energy-optimized systems, and long-term reliability.

Effluent Treatment Plants

Our customized ETP solutions tackle diverse industrial effluents, leveraging primary, secondary, and tertiary treatments to meet discharge regulations. Every system is engineered for minimal footprint, low operating cost, and robust process control.

Reverse Osmosis & Desalination

We specialize in high-recovery RO systems that deliver consistent, high-quality water. Our designs focus on durability, scale prevention, energy efficiency, and ease of maintenance to maximize system lifespan and water reuse.

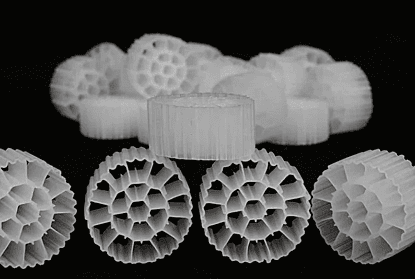

Moving Bed Biofilm Reactor Technology

Zero Liquid Discharge

Our ZLD solutions utilize advanced evaporation, crystallization, and polishing to recover water and minimize waste. Designed for sustainability, they help industries achieve water neutrality and comply with the strictest environmental standards.

Annual Maintenance Contract

We offer tailored AMC packages to keep your water and wastewater systems running at peak performance. From regular service checks to emergency support, our proactive approach prevents downtime and prolongs equipment life.

Address & Location

301, Block A

Diamond Business Center

Arjan, Al Barsha South 3

Dubai, United Arab Emirates