Smarter Bio-Treatment. Smaller Footprint.

MBBR Systems Designed for Performance, Efficiency, and Scalability

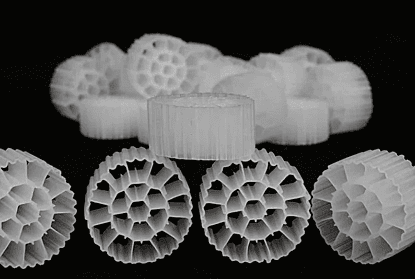

MBBR (Moving Bed Biofilm Reactor) is a cutting-edge biological treatment technology that uses specially designed plastic media suspended in aeration tanks to grow active biofilm. The result is a high-efficiency system that can handle fluctuating loads, requires less space, and minimizes sludge production.

Built for Industries That Demand Smarter, Space-Saving Treatment

MBBR systems are ideal for industries that require stable biological treatment with minimal space and low energy use.

Residential & Commercial STPs

Space-efficient MBBR units ideal for housing, offices, malls, and hotels where footprint and odor control are key.

Textile & Dyeing Wastewater

Effectively reduces high organic loads in wastewater with minimal maintenance and high operational uptime.

Food & Beverage Processing

Tackles high-COD biodegradable loads with fast biomass response and robust process control.

Pharmaceutical Manufacturing

Supports high-strength effluent treatment with stable, biofilm-based removal of complex organic compounds.

Industrial Retrofitting

A practical upgrade solution for underperforming ASP systems, enabling enhanced capacity without large civil changes.

Residential & Commercial STPs

Compact MBBR units are ideal for apartments, malls, and offices, offering reliable treatment with minimal space and odor.

Frequently Asked Questions

Explore Our Other Solutions, Services & Technologies

Integrating proven treatment processes and advanced technologies to deliver reliable, high-performance water management systems built for long-term operation.

Sewage Treatment Plants

We design and build high-efficiency STPs using proven biological and physical-chemical processes to ensure compliant, odor-free discharge or reuse. Our expertise covers advanced automation, energy-optimized systems, and long-term reliability.

Effluent Treatment Plants

Our customized ETP solutions tackle diverse industrial effluents, leveraging primary, secondary, and tertiary treatments to meet discharge regulations. Every system is engineered for minimal footprint, low operating cost, and robust process control.

Reverse Osmosis & Desalination

We specialize in high-recovery RO systems that deliver consistent, high-quality water. Our designs focus on durability, scale prevention, energy efficiency, and ease of maintenance to maximize system lifespan and water reuse.

Moving Bed Biofilm Reactor Technology

Zero Liquid Discharge

Our ZLD solutions utilize advanced evaporation, crystallization, and polishing to recover water and minimize waste. Designed for sustainability, they help industries achieve water neutrality and comply with the strictest environmental standards.

Annual Maintenance Contract

We offer tailored AMC packages to keep your water and wastewater systems running at peak performance. From regular service checks to emergency support, our proactive approach prevents downtime and prolongs equipment life.

Address & Location

301, Block A

Diamond Business Center

Arjan, Al Barsha South 3

Dubai, United Arab Emirates